Our research work is focused on the development (Arc-Melting, Melt-Spinning, Splat-Cooling, Microwave, Alloying) and characterization (Rietveld) of intermetallic composite materials at micro and nano scale. Materials dedicated for permanent magnets and magnetocaloric materials, efficient hydrogen storage, batteries and perovskites/electrolytes for solid oxide fuel cells are investigated for understanding the relation between structural characteristics and properties. Magnetic or conductive nanoparticles mixed with various polymeric materials (acrylates, silicones, styrene, natural or biodegradable polymers etc). COMSOL multiphysics is one of our main activities on Energy Systems (Tanks, Fuel Cells, Magnetic Brake).

Solid-state storage refers to the storage of hydrogen in metal hydrides, in chemical storage materials, and in nanostructured materials. This method of hydrogen storage offers perhaps the best opportunities for meeting the requirements for onboard storage. Reversible storage means that hydrogen is released by raising the temperature of, for example, a metal hydride at a suitable pressure; hydrogen is subsequently replaced (stored) through the control of temperature and hydrogen pressure. Ideally, storage and release of hydrogen should take place at temperatures between 0 °C and 100 °C and pressures of 1–10 bar and on time scales suitable for transportation applications. Some materials contain strongly chemically bound hydrogen that is not readily retrievable. Only hydrogen that can be made easily accessible will meet the hydrogen storage requirements.

Renewable Energy issues and TRNSYS model have been used for our research work.

While rare-earth permanent magnets based on NdFeB have applications in efficient motors and generators with a high energy density, are cost-effective and have excellent magnetic properties at room temperature, they suffer from a loss of magnetic properties at elevated temperatures. By contrast, recently-developed SmCo-based magnetic alloys can retain useful magnetic behaviour to temperatures of ~550ºC, making them ideal for aero-engine applications such as frictionless bearings or co-axial starter-motors/generators. The aim of our group is to study the structural, microstructural and magnetic properties of the SmCo-based magnetic alloys fabricated following various innovative approaches.

Magnetic or conductive nanoparticles mixed with various polymeric materials (acrylates, silicones, styrene, natural or biodegradable polymers etc).

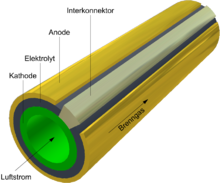

Perovskites are mixed oxides with the general formula ABO3. Many different compositions have been found to be possible and their number is growing rapidly due to their characteristics that make them ideal for various applications, among which is the fabrication of cathodes for solid oxide fuel cells (SOFCs). It is important for these solids that they maintain their electro-neutrality and the A and B cations are stable.

Ceria-based solid solutions are regarded as the most promising electrolytes for the intermediate temperature fuel cells because their ionic conductivity is high enough to meet the intermediate temperature applications.

Materials & Processes for Energy & Environmental Applications Group / Department of Environmental Engineering, University of Patras

InnoEnergy Lab / Privacy Policy / Copyright 2020 / Developed by DigiLab